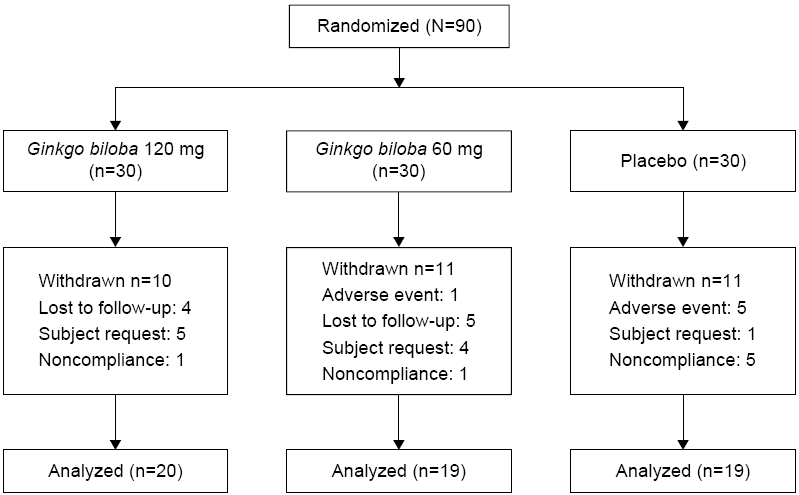

Ginkgo leaf disturbance in 2015

In 2015, due to the use of inferior raw materials, it was arbitrarily changing the production process of Ginkgo biloba extract, which caused a number of domestic manufacturers involved in the storm of Ginkgo biloba. These companies arbitrarily changed the extraction process and used 3% dilute hydrochloric acid instead of dilute ethanol to prepare Ginkgo biloba extract. Not only can it save 4,000 yuan per ton, but it can also increase the yield and shorten the basic process time. However, this process seriously affects the safety and efficacy of drugs. Today we will help you explain the disadvantages of dilute hydrochloric acid extraction of ginkgo preparations!

Ginkgo Extracted with Hydrochloric Acid

- Dilute hydrochloric acid extraction method will reduce the active ingredients in Ginkgo biloba extract, far less than the standards of the Chinese Pharmacopoeia, especially the large decomposition of azlactone, and ultimately lead to lower product efficacy.

- 2. In terms of safety, the hydrochloric acid extraction method will increase the content of harmful ingredients such as ginkgolic acid in the extract, thus affecting the safety of the product.

- Hydrochloric acid extraction will cause some harm to the environment. The waste water extracted by hydrochloric acid from Ginkgo biloba leaves contains a large amount of acidic waste liquid of ginkgolic acid. If this kind of acidic waste liquid is improperly treated, it will pollute the water body and cause serious damage to the environment

Ginkgo biloba extract process

When it comes to the extraction process of Ginkgo biloba, there are two types widely used at home and abroad: water-acetone extraction and water-ethanol extraction. Take Danacon® (Egb761) as the benchmark product of Ginkgo biloba extract, which is a water-acetone two-phase extraction method. The production process is crude extraction with water-acetone as the starting solvent, followed by degreasing. , Remove ginkgo phenolic acid, active ingredients enrichment, purification and other dozens of complex processes, made of extracts.

About herb extract

As we all know, the quality of botanical drugs depends on many factors such as the source of raw materials, quality control, production processes and equipment, and extraction process is undoubtedly the most important part. To some extent, to choose a product is to choose a process standard that is to choose quality and reputation. For example, the above-mentioned EGB761, which represents a higher standard in the industry, has strict quality control, innovative patented production processes, and its active ingredient content is of high purity and proportion.

Sangherb Ginkgo biloba extraction production

Snagherb biology more than hundreds of kinds of standard reference material. Sangherb is always controlling quality from raw materials to every step during production. Except the control for active ingredients content, the controlling of pesticide residue and heavy metal can meet the USP standard at the same time. We are in firm belief that quality and innovation are the key to better ourselves as well as benefit our clients.

Leave A Comment